OSHA Code Violations and Citation Abatement

OSHA’s Mission

With the Occupational Safety and Health Act of 1970, Congress created the Occupational Safety and Health Administration (OSHA) to ensure Safe and Healthful working conditions for workers by setting and enforcing standards and by providing training, outreach, education, and assistance.

At B and W Compliance, our first priority is to establish a Safe and Healthful environment for our clients’ workplaces through regular inspections, corrections, and employee training that complies with OSHA standards. This not only has the result of a reduction of safety hazards for employees, the ultimate priority, it also reduces the chance of incurring an OSHA citation in the first place.

The purpose of OSHA inspections and citations is simply to ensure all employees have the Safe and Healthful work environment they deserve.

It’s important that employers and employees are informed of additional consequences for not following established safety protocols, to reinforce understanding and compliance of Safety and Health standards.

VIOLATIONS & PENALTIES

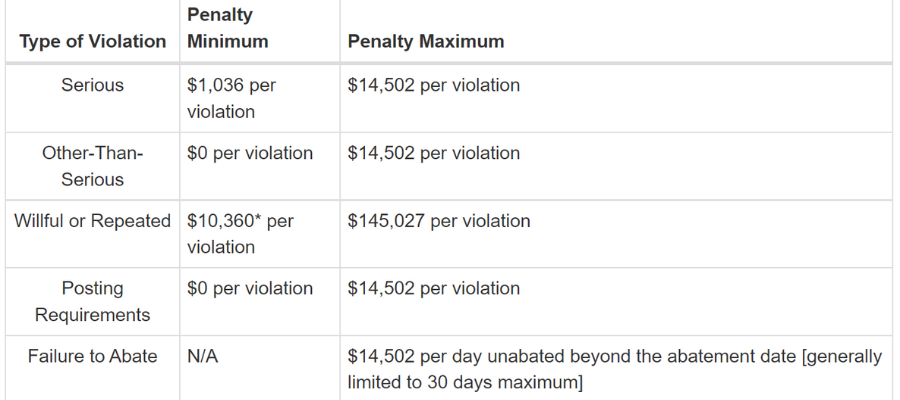

When it comes to penalties assessed for OSHA code violations, there are five main classifications to be aware of:

- Regulatory Violations

- General Violations

- Serious Violations

- Repeat Violations

- Willful Violations

The most expensive violations include those that are Serious, Repeated, and Willful because they reflect severe penalties for employers who are not taking care to ensure their employees have a workplace environment that is free from hazards.

Regulatory Violations

Regulatory violations are those that pertain to permit, posting, recordkeeping, and reporting requirements as established by regulation or statute.

Examples of regulatory violations include, but are not limited to:

- Failure to obtain a necessary permit;

- Failure to publicly post a citation or required employment posters;

- Failure to keep necessary and required records;

- Failure to report work-related accidents and injuries, etc.

General Violations

A general violation is a compliance violation related to Employee Safety and Health that OSHA does not categorize as a serious violation.

Serious Violations may sometimes be reduced to General Violations if the employer can show that they took all the steps a reasonable and responsible employer in similar circumstances should be expected to take, before the violation occurred, to anticipate and prevent the violation.

Factors OSHA might take into account to reduce a violation to “general,” may include such things as:

- Employee and supervisor training related to preventing the hazard or similar hazards;

- Established procedures for discovering and correcting the hazard or similar hazards; and

- Procedures for communication to employees about the employer’s Health and Safety protocols and programs, etc.

If for any reason a citation were to be given for a Serious Violation, having established Safety and Health programs along with employee training, shows OSHA the company has observed compliance and taken appropriate steps to keep their employees safe.

Serious Violations

Violations categorized as “serious” include those compliance issues where there is a realistic possibility that the hazard created by the violation may result in death or serious physical harm to employees.

Two main examples of hazards outlined by OSHA code that fall under serious violations, include:

1. An exposure that exceeds an established allowable exposure limit;

2. One or more unsafe or unhealthful practices, means, methods, operations, or processes in use in the workplace.

Allowing employees to work with hazardous materials without the proper Personal Protective Equipment (PPE) could be considered a serious hazard violation if it might lead to an employee getting severely ill or possibly dying.

Examples of this include such things as laboratory staff wearing the appropriate gloves and having a properly fit-tested N95 respirator mask when required.

Our inspections of your location have the purpose of calling out any possible hazards that could lead to serious violations so we can help you get them resolved and ensure your workplace is hazard free. It’s important that when a violation is found, we work quickly to resolve it and create a safe work environment for all employees.

One of the best ways to prevent serious hazards is to have regular inspections and analyses done in the workplace. Which is why inspection is the first thing our consultants do when visiting a new client.

Repeat Violations

A repeat violation happens when a previous OSHA citation for a specific violation has been abated, and a later OSHA inspection (within five years) finds the same or similar conditions or hazards.

For obvious reasons, the penalties for continuing to create a hazardous condition that has already been abated will be much higher than in an initial citation.

Willful Violations

A willful violation is one where there is evidence that the employer is conscious and aware of the fact that what they are doing is a violation of safety law, or was aware that an unsafe or hazardous condition existed, but made no reasonable effort to eliminate the hazard.

Willful and repeat violations can result in penalties as high as $145,027 per violation.

In addition to the fact that the employer is 100% responsible for creating a safe environment for employees, a good employer will always ensure that resolving safety concerns is a top priority.

Anyone intentionally creating a hazardous environment for employees is working to go out of business, and OSHA will not be lenient.

(GBP, as shown above, stands for Gravity Based Penalty, which is a system used by OSHA to set minimum penalties for violations based on their severity.)

Various states, such as California, have their own OSHA programs with penalties that are required to adopt maximum penalty levels that are “at least as effective as Federal OSHA’s.” You will not see penalties set any lower than what is shown in the table, above.

CITATION ABATEMENT

As it applies to OSHA citations received by employers, abatement means to take action to comply with cited standards or regulations and eliminate recognized hazards defined by OSHA during an inspection.

Abatement verification is the process in which an employer informs OSHA, any affected employees, and their representatives, that a cited hazard has been corrected. Generally, this includes submitting evidence of having established appropriate Safety and Health programs, including regular inspections and corrections, as well as employee safety training and any actions taken to eliminate hazardous conditions found on inspection.

B and W Compliance, Inc. has worked very successfully with OSHA in abating scores of citations. In doing so, we always keep OSHA’s Mission as well as ours to ensure safe and healthful working conditions for workers in the forefront.

Say What You See!

The essence of any Safety & Health program that is successfully conducted in a group of any size is “TEAMWORK”. The safety and health of any workplace is contingent on not only safe practice by the individual, but also observance of what is going on around oneself.

It is important for employees to observe and communicate hazards or potential dangers and to correct or get these corrected. If the hazard is simple (wet floor) then it can simply be dealt with. A more complicated hazard (broken machine) requires more action by the observer; write a note regarding the hazard to the office manager or owner for repair and post a sign on the broken machine warning others.

If any employee observes a violation of a safety protocol or regulation, including any conditions which are hazardous to employees, they should take care of it as best they can and additionally report the details of the situation to their designated workplace Safety Administrator, supervisor, or employer.

It is the responsibility of all employees to ensure a Safe and Healthful workplace for everyone.

Managers and general employees should read this article to understand the importance of following their Safety and Health program protocols and OSHA’s role in enforcing them.

We’d Love to Hear from You!

If you have any questions or need further information regarding this month’s newsletter topic, please don’t hesitate to contact our office or your personal consultant. Your feedback and comments are always appreciated.